SATS and Dassault Systèmes have announced that they have successfully implemented the world’s first digital twin experience of a central kitchen to enhance SATS’ inflight kitchen operations. The partnership will help SATS identify new ways to boost efficiency and minimise food waste, for a more sustainable approach to its operations.

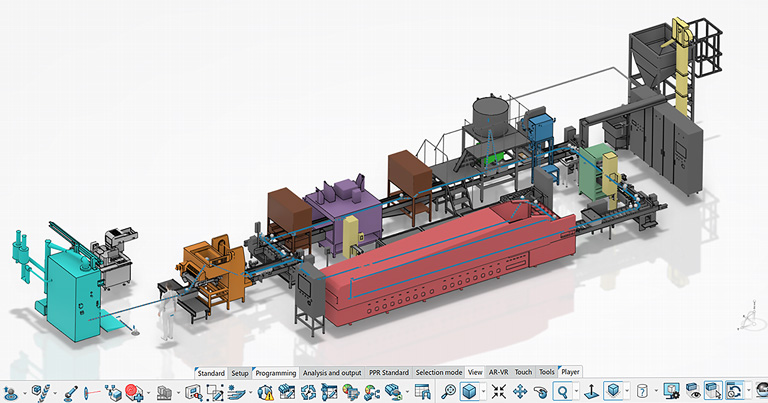

SATS used Dassault Systèmes’ 3DEXPERIENCE platform on the cloud to create a 3D digital twin experience of a virtual kitchen that pairs virtual and physical operations to provide data-driven analytics for better resource planning. SATS can capture decades of operational know-how to simulate different food production processes in order to improve capacity planning and production scheduling, prevent bottlenecks, and enhance productivity. Moreover, the solution will allow for better forecast ingredient usage in its large-batch food production to reduce food wastage.

The virtual kitchen captures and integrates all process data and information into one 3D virtual environment to ensure consistency, enabling the facility’s operation managers to respond faster and more efficiently to changing situations.

“SATS takes a technology-driven, people-led approach to growth, harnessing the power of technology and unleashing the innovation of our people to create new services and improve operational efficiency,” said Albert Pozo Hernandez, Chief Digital Officer, SATS Ltd. “The use of digital twin technology helps SATS to simulate different production scenarios and cooking processes to optimise resources within our kitchens. We selected Dassault Systèmes because of its powerful 3D visualisation and data management tools that enable us to make more informed, data-driven business decisions to ensure SATS consistently delights our customers.”

Guillaume Vendroux, CEO, DELMIA, Dassault Systèmes, added that this is the first time that the 3DEXPERIENCE platform has been deployed in inflight catering production. He said: “SATS can optimise resources by mapping the virtual model to the physical processes of their in-flight catering operations, and dynamically modelling, simulating, and analysing every life cycle of production.”